Description

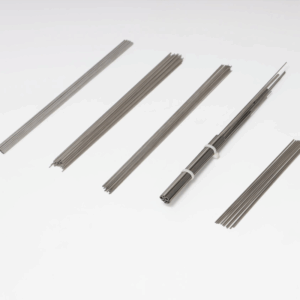

Product Overview: Crimping Nitinol Wire (0.0085″ x 73.0″)

The Crimping Nitinol Wire (0.0085″ x 73.0″) is precision-crafted from a nickel-titanium alloy, offering remarkable strength, flexibility, and shape memory capabilities. When exposed to heat, it reliably returns to its preset form, making it ideal for medical, aerospace, and robotics applications.

Material Properties

Nitinol combines nickel and titanium in a precisely balanced ratio, creating a unique metal with a shape memory effect. This allows the wire to regain its original shape after deformation, making it highly valuable for intricate engineering and medical uses.

Why It Matters:

- High precision and reliability

- Exceptional resilience and durability

- Maintains strength and performance across a range of temperatures

Surface Finish

The surface finish of Crimping Nitinol Wire impacts its high superelastic performance. Options like polished, coated, or anodized finishes reduce friction and minimize wear.

- Polished Finish: Enables smooth navigation in medical guidewire applications.

- Coated Surface: Provides added protection against corrosion and wear as PTEF etc.

- Anodized Finish: Enhances surface durability and reduces surface imperfections.

Dimensions and Applications

With a diameter of 0.0085 inches and a length of 73.0 inches, this Nitinol wire delivers precision across industries:

- Medical Devices: Enables precise placement and deployment of guidewires, stents, and other minimally invasive tools.

- Robotics and automation benefit from this wire’s dependable motion and long-lasting strength, ideal for micro-actuators and precise devices.

- Aerospace and Automotive: Supports complex applications that require a strong, flexible material that can return to its original form.

Why Choose Crimping Nitinol Wire?

- Superior shape memory and superelasticity

- Enables highly intricate, precision applications

- Reduced risk of deformation or fatigue

- Ideal for medical, aerospace, robotics, and consumer electronics

•Diameter & Tolerance

| Diameter(mm) | Tolerance(mm) | Diameter(mm) | Tolerance(mm) | Diameter(mm) | Tolerance(mm) |

| 4.000-2.000 | ±0.025 | 0.350-0.260 | ±0.010 | 0.08-0.050 | ±0.005 |

| 2.000-1.000 | ±0.020 | 0.260-0.150 | ±0.007 | 0.050-0.025 | ±0.005 |

| 1.000-0.350 | ±0.010 | 0.150-0.080 | ±0.005 | 0.025-0.018 | ±0.003 |

•Mechanical properties

| Max force(N) | Tensile(MPa) | Elongation % | Upper stress(MPa) | Residual strain(WT%) | At temp |

| Base on diam | ≥1000 (1350) | ≥10 (15) | ≥400 (460) | <0.5 55.96 | (10±10) |

| Base on diam | ≥1000 (1350) | ≥10 (15) | ≥400 (460) | <0.5 56.1 | (-30±10) |

| Base on diam | ≥1000 (1350) | ≥10 (15) | ≥400 (460) | <0.5 50.0 | (60±10) |

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

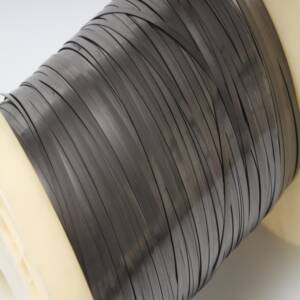

Nitinol Flat wire– Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Nitinol Tube – Precision-engineered tubing ideal for minimally invasive devices and high-performance systems.

Reviews

There are no reviews yet.